Application Pain Points and Requirements

Harsh Environment

Safety and Reliability

Regular Maintenance

Milling Machine Door Locks Need to Meet the “Universal Unlocking” Requirement

That is, one key can open all locks on the milling machine.

Supporting Components

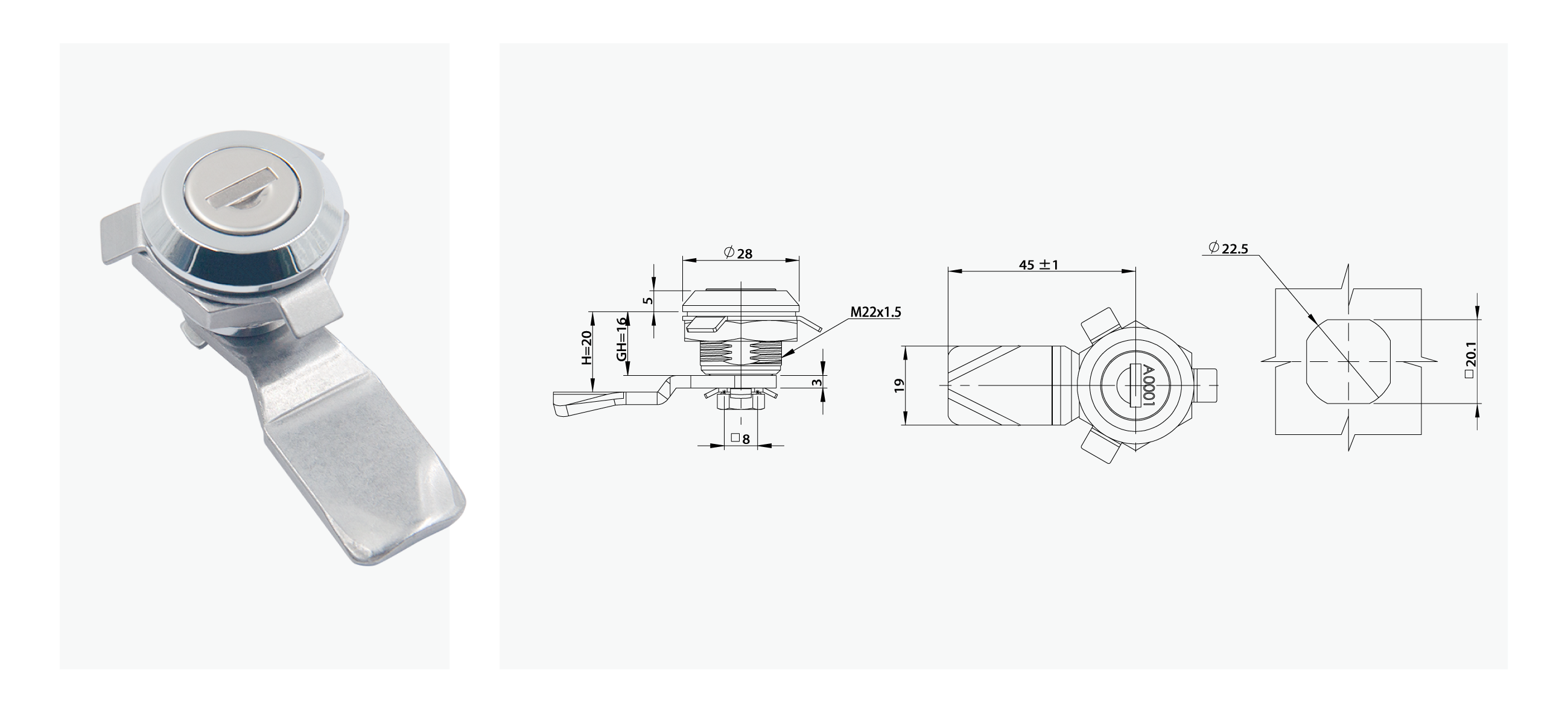

Cylindrical Lock MS705-3E-8D

The MS705 - 3E - 8D cylindrical lock is made of zinc alloy and undergoes bright chrome surface treatment, boasting excellent texture and corrosion resistance. It adopts a rotary locking mode matched with a wafer lock core, enabling convenient operation and good anti - theft performance. The steel bolt has a bearing capacity of up to 200N, ensuring reliable load - bearing. Meanwhile, it features strong adaptability in dimensions such as hole opening, and can efficiently match installation scenarios. It is a practical industrial lock.

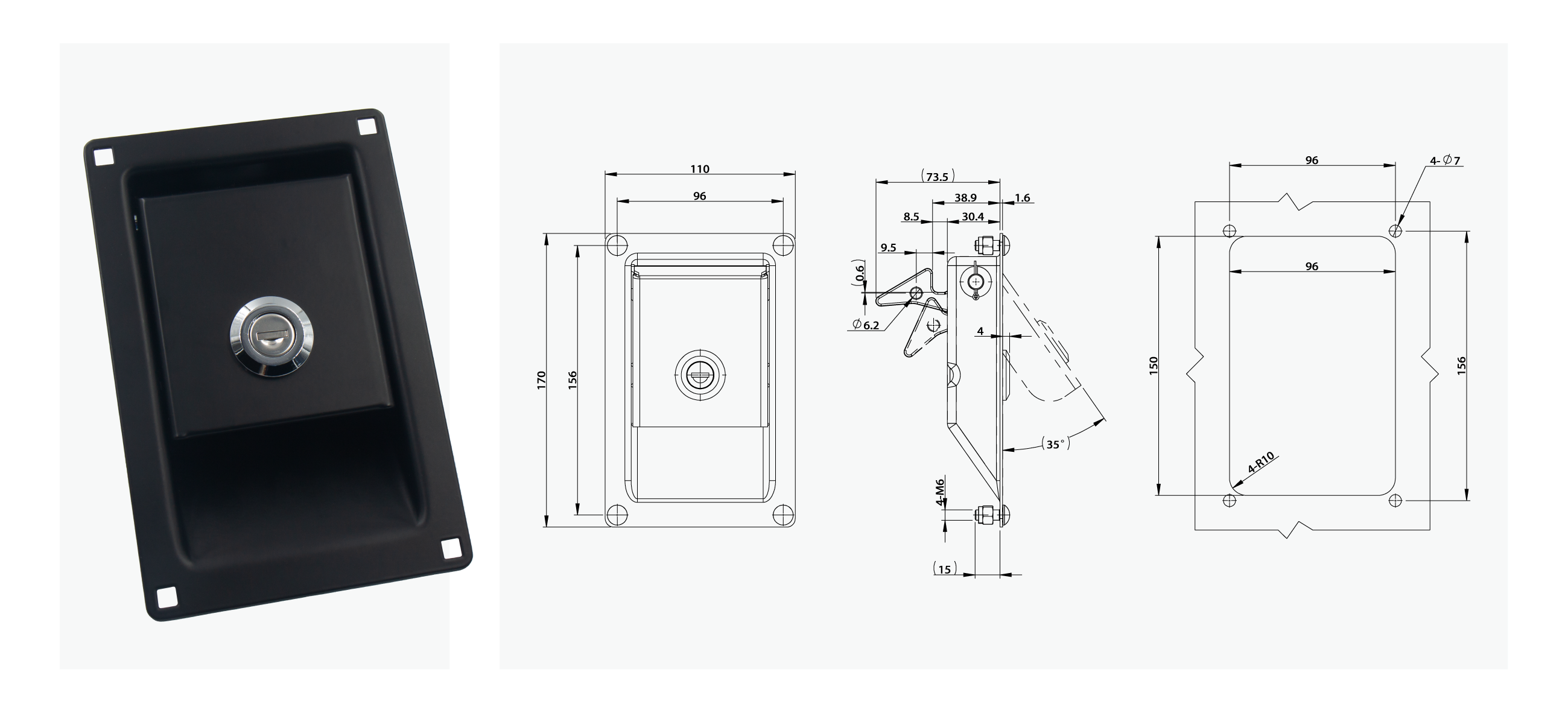

Panel Lock MS866-33-1D

The MS866 - 33 - 1D panel lock adopts a convenient card - type locking method, is made of iron and undergoes powder coating treatment, making it durable and protective. Equipped with a wafer lock cylinder, it has good anti - theft performance. The steel bolt has a bearing capacity of ≥3N and the key torque is ≥2.5N, ensuring reliable mechanical properties. With a square opening size of 145*89, it has strong adaptability and is a practical industrial panel lock.