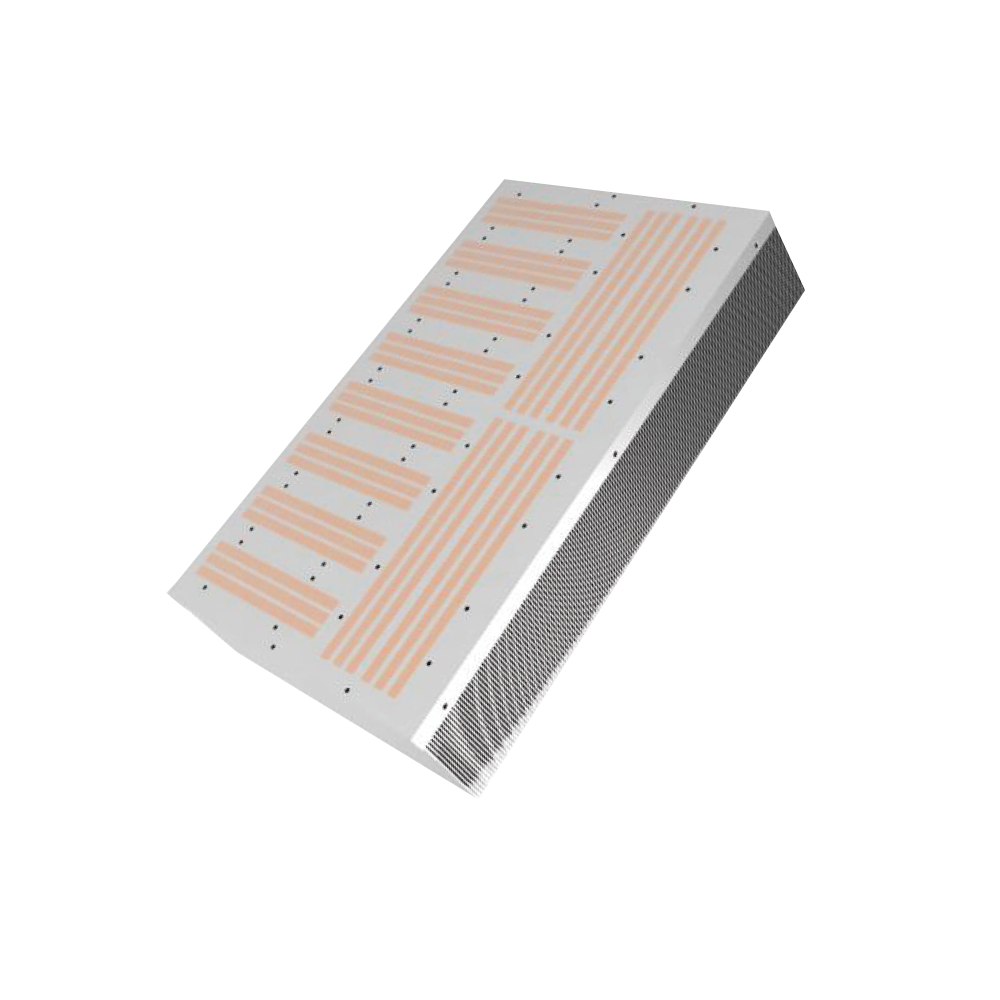

Forming Process: Adopts the combined process of "skived fin + heat pipe" — skived fin process expands the heat dissipation area, while the heat pipe is responsible for efficient heat conduction; the combination realizes rapid heat diffusion and export

Welding Process: Buried copper heat pipe process, which firmly combines the copper heat pipe with the radiator substrate to ensure the continuity of heat conduction

Application Scope: Adaptable to the actual needs of the system

Thermal Performance Advantage: Has uniform temperature characteristics, which can evenly distribute heat through the heat pipe to avoid local overheating; at the same time, combined with the design of skived fin and copper heat pipe, it achieves high heat transfer efficiency and quickly exports equipment heat

Process Adaptability Advantage: The buried copper heat pipe process enhances the tight combination of the heat pipe and the substrate, reducing heat conduction loss; the skived fin process further increases the heat exchange area with air

Material Advantage: Aluminum alloy material has both lightweight characteristics and good thermal conductivity, adapting to the needs of equipment for "weight reduction + high-efficiency heat dissipation"

Core Requirement: All dimensions shall be customized according to customer requirements

Relevant Description: Drawing details such as skived fin layout, heat pipe specifications, and substrate structure need to be synchronized with the customer's system heat dissipation needs

Privacy Policy

Data update in progress......

+0086-574-87845333

info@shengjiu.com

Sengjiu Road No 1, Dayin Town, Yuyao City, ZheJiang Province,China 315423