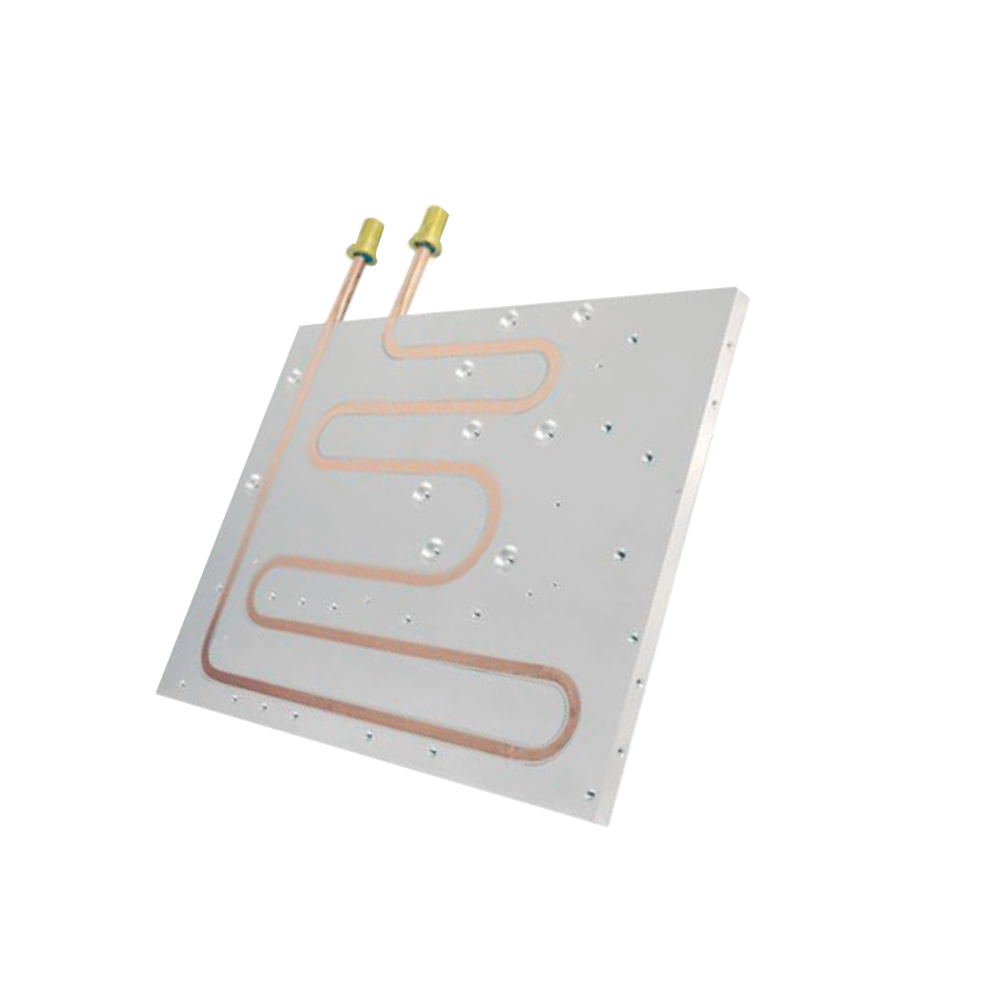

Material Combination: Adopts the composite material of aluminum alloy + red copper tube — aluminum alloy ensures the basic rigidity of the liquid cooling plate, while red copper tube enhances heat dissipation efficiency with its high thermal conductivity

Forming Process: Completed by "tube bending (customizing the shape of copper tube flow channel) + CNC machining (processing the aluminum alloy substrate and matching the copper tube installation structure)"

Welding Process: Uses buried copper tube + glue filling process to achieve a stable combination of copper tube and substrate

Application Scope: Adaptable to the actual needs of the system

Material Adaptability Advantage: The combination of aluminum alloy (rigidity) + red copper tube (high thermal conductivity) balances the structural stability of the liquid cooling plate and heat dissipation performance

Customization Flexibility Advantage: The flow channel form of the copper tube can be determined according to specific heat dissipation needs, adapting to the heat dissipation scenarios of different equipment

Structural Reliability Advantage: Buried installation combined with glue filling process not only ensures the sealing between the copper tube and the substrate, but also maintains the overall rigidity of the liquid cooling plate

Core Requirement: All dimensions shall be customized according to customer requirements

Relevant Description: Drawing details such as the flow channel form of the copper tube and the structure of the aluminum alloy substrate need to be synchronized with the customer's system and heat dissipation needs

Privacy Policy

Data update in progress......

+0086-574-87845333

info@shengjiu.com

Sengjiu Road No 1, Dayin Town, Yuyao City, ZheJiang Province,China 315423