CNC machines are the cornerstone of modern manufacturing, known for their precision, speed, and versatility. However, operating at such high performance generates significant heat, which, if left unmanaged, can jeopardize the machine's functionality and lifespan. DC cooling fans are a critical component in CNC systems, providing reliable thermal management to ensure machines run efficiently and safely under demanding conditions. This article Shengjiu explores the technical features and critical role of DC cooling fans in CNC operations.

The Critical Role of DC Cooling Fans in CNC Operations

Ensuring Component Protection

CNC machines consist of multiple high-value components such as spindles, control units, and power electronics. Excessive heat can cause these components to malfunction, degrade, or fail entirely, leading to costly repairs and production downtime. DC cooling fans address this issue by dissipating heat effectively and maintaining a stable operating temperature.For instance, servo motors in CNC machines are responsible for precise movements and positioning. Without adequate cooling, these motors can overheat, resulting in inaccurate operations or permanent damage. DC cooling fans provide consistent airflow to prevent thermal stress, safeguarding the machine's most critical components.

Enhancing Operational Reliability

In industrial environments, unplanned downtime caused by overheating can severely impact productivity. Thermal shutdowns or performance drops not only delay production but also compromise product quality. DC cooling fans ensure that CNC machines operate within safe temperature ranges, enabling consistent performance and reducing the risk of unexpected failures.For example, in automotive manufacturing plants, CNC machines often run continuously to meet high-volume production demands. By incorporating advanced DC cooling fans, manufacturers can maintain the machines' reliability and keep operations running smoothly, even during extended shifts.

Maintaining Precision and Accuracy

CNC machining is synonymous with precision. However, thermal fluctuations can lead to dimensional inaccuracies and defects in the final product. DC cooling fans mitigate these risks by maintaining a stable thermal environment, ensuring that the machine's structural components and tools remain unaffected by heat.In industries such as aerospace or medical device manufacturing, where precision is critical, DC cooling fans play a vital role in ensuring that every part meets exact specifications. Their ability to regulate temperatures prevents the minute distortions that can compromise the quality of high-precision components.

Technical Features of Advanced DC Cooling Fans

Optimized Airflow and Static Pressure

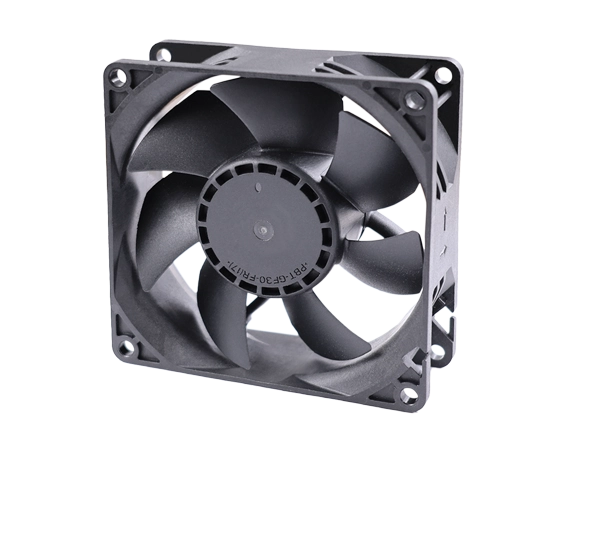

The efficiency of a cooling fan hinges on its ability to generate sufficient airflow and effectively handle static pressure. Advanced DC cooling fans are specifically engineered to strike a balance between these two critical factors. By incorporating precision-designed blades and aerodynamic housing, these fans optimize airflow, ensuring that heat is efficiently expelled from CNC machines. Static pressure management is equally crucial, as many CNC systems have tightly packed components and restricted airflow paths. Advanced fans are equipped with high-performance motors and blade geometries that maintain consistent airflow even under high static pressure. This design ensures that heat is dissipated efficiently, preventing thermal hotspots and maintaining the reliability of critical components like spindle motors, control units, and circuit boards.

Energy-Efficient Designs

Energy efficiency is a cornerstone of advanced DC cooling fan technology, especially in industrial environments where energy costs can accumulate rapidly. These fans are designed to consume minimal power without sacrificing performance, making them ideal for facilities where multiple CNC machines operate simultaneously. Brushless DC motors play a significant role in enhancing energy efficiency. These motors reduce power loss through advanced electronic commutation, resulting in smoother operation and lower energy consumption. Furthermore, energy-efficient designs contribute to reduced heat generation within the fan itself, further improving operational reliability. By investing in such fans, manufacturers can achieve lower operational costs, reduced carbon footprints, and more sustainable production processes.

Durability for Industrial Environments

CNC machining environments are often characterized by high levels of dust, moisture, vibrations, and temperature fluctuations. Advanced DC cooling fans are constructed with materials and technologies that ensure their durability in these harsh conditions. Corrosion-resistant metals, such as stainless steel or aluminum alloys, are used for critical fan components, ensuring resistance to humidity and chemical exposure. Additionally, durable polymers with heat-resistant and anti-static properties are employed in fan housings to enhance protection against environmental stressors. Sealed ball bearings and vibration-damping mounts further enhance the fan's reliability by reducing wear and tear on moving parts, even under constant operation. Some fans also feature IP-rated enclosures that protect against dust and water ingress, ensuring uninterrupted performance. This robust construction ensures a long operational life, reducing maintenance needs and preventing unexpected downtime in demanding industrial applications.

DC cooling fans are a cornerstone of effective thermal management in CNC machining, delivering superior cooling performance that protects critical components, enhances reliability, and maintains precision. Their advanced features, including optimized airflow, energy efficiency, and robust durability, make them indispensable in modern manufacturing environments.By selecting the right DC cooling fans and adopting best practices for their maintenance and integration, manufacturers can maximize the efficiency and lifespan of their CNC machines.