Charging piles are specialized devices for charging Electric Vehicles (EVs), serving as an alternative to traditional gas stations and air pumps. They consist of pile bodies, electrical modules, and metering modules, and most are equipped with functions such as electric energy metering, billing management, communication interconnection, and power regulation.

Currently, China is the country with the strongest comprehensive policy support in the field of charging infrastructure globally. Policies cover multiple dimensions including the construction of charging infrastructure, power access guarantee, and charging facility operation management. The National Energy Administration once set a target: by 2020, to add over 12,000 centralized charging stations and more than 4.8 million decentralized charging piles to meet the charging demands of 5 million new energy vehicles. For this reason, to ensure the healthy and rapid development of the charging pile industry, governments at all levels have introduced a series of supportive policies in terms of regulatory norms, subsidy incentives, and other aspects.

Application Scenarios and Technical Requirements

Adaptation to Harsh Working Environments: Charging piles are usually deployed in outdoor scenarios, which have relatively high requirements for protection class. Generally, they need to reach IP54 or above and should have flame - retardant performance.

High Safety Standards: Charging piles often stay in an unattended state, and electrical safety must be guaranteed during operation. During the charging process, the internal modules of the charging pile can only perform charging operations after the external door is opened and relevant internal doors are closed. Therefore, there are clear requirements for the anti - theft and anti - misoperation performance of locks.

Integration of Industrial Design and Function: Cabinet - type equipment needs to balance operational convenience (such as door opening and operation & maintenance convenience) and safety protection, requiring a high degree of integration between industrial design and function realization.

Long Service Life and Corrosion Resistance: Products need to have long - term durability and corrosion resistance, with a designed service life of no less than 10 years; in year - round outdoor use scenarios, locks and supporting components also need to meet the same weather resistance and corrosion resistance requirements.

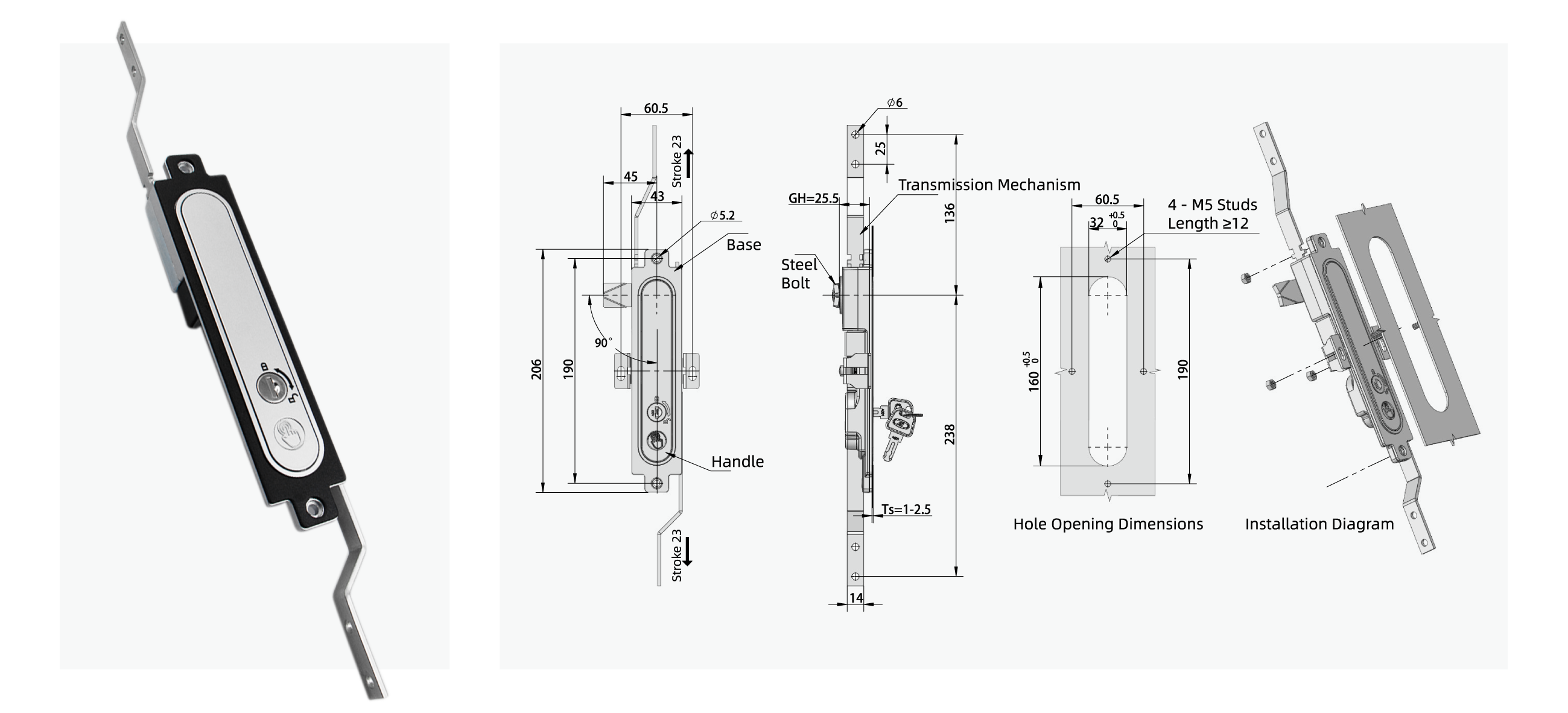

Linkage Lock MS999

MS999 lock is constructed from ADC12. Its surface treatments are available in options including high salt spray resistant black, nano matte, and technical gray. The structure can be left-handed or right-handed. In terms of performance, the handle has a bearing capacity of 300N and a torque of 45N·m, with an H value of 25.5mm. It adopts a special-shaped orifice plate for opening and is compatible with plates with a thickness of 1~3mm.

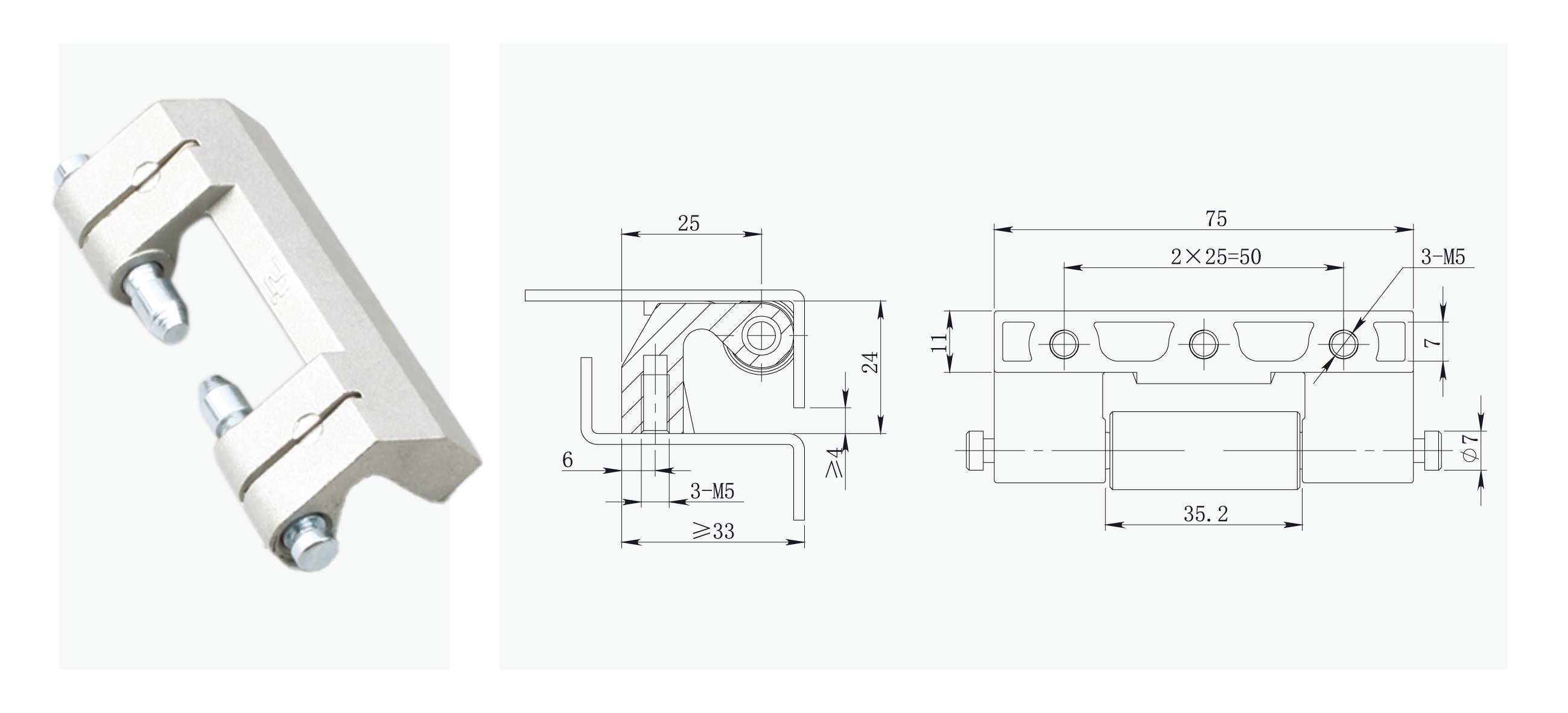

Hinge CL201-1

Hinge CL201-1 adopts zinc alloy for the hinge body, carbon steel for the pin and accessories. In terms of performance, when the tubular accessory is selected, the radial load of the maximum static load is 800N, and the axial load is 1500N.